by ClaytonEng1 | Jun 13, 2025 | News

3 Big Retirements in 2025! In 2025, we have had three 30+ year employees retire! Early in January, we wished a congratulations to long time Project Manager Ken Schaeffler, and thanked him for the friendship, service and golf. His expertise has been an invaluable...

by ClaytonEng1 | Oct 27, 2024 | News

2024 Bommarito Construction Pink Ribbon Good This month Clayton Engineering joined Bommarito Construction in supporting the Pink Ribbon Good fundraiser with the goal of turning the entire St. Louis construction industry pink by wearing pink every Friday in October....

by ClaytonEng1 | Oct 27, 2024 | News

2024 Ranken Jordan’s 5k for Play Presented by the Young Professionals Board Saturday, October 26, 2024 Clayton Engineering was a returning sponsor at the 2024 5K for Play to support Ranken Jordan Pediatric Bridge Hospital! Employees participated with their...

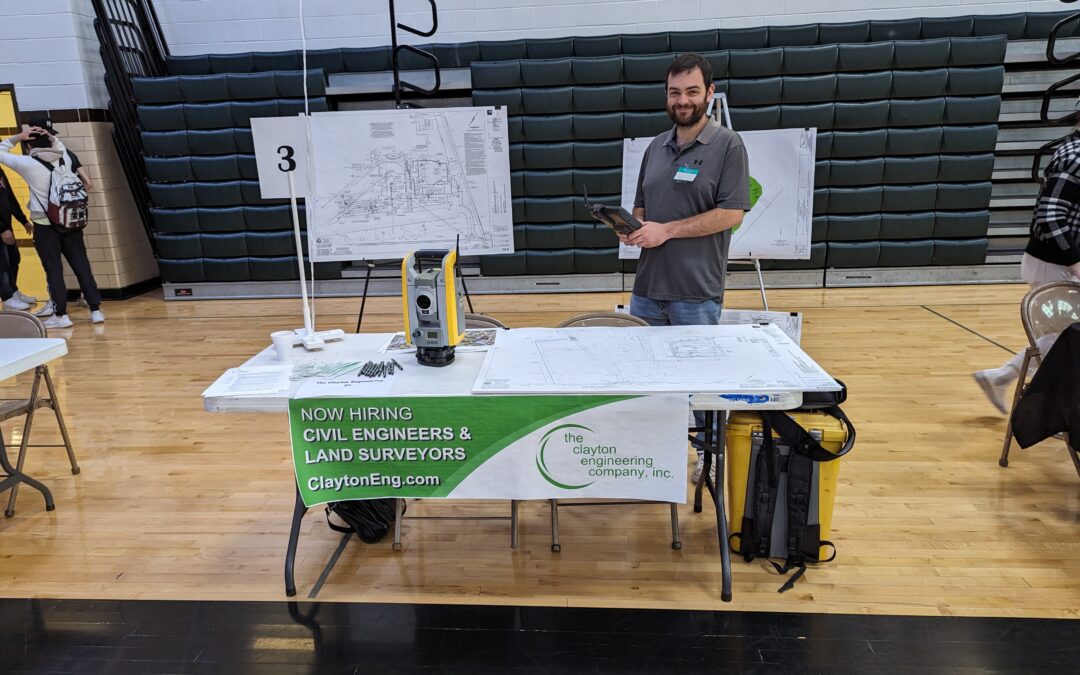

by ClaytonEng1 | Oct 11, 2024 | News

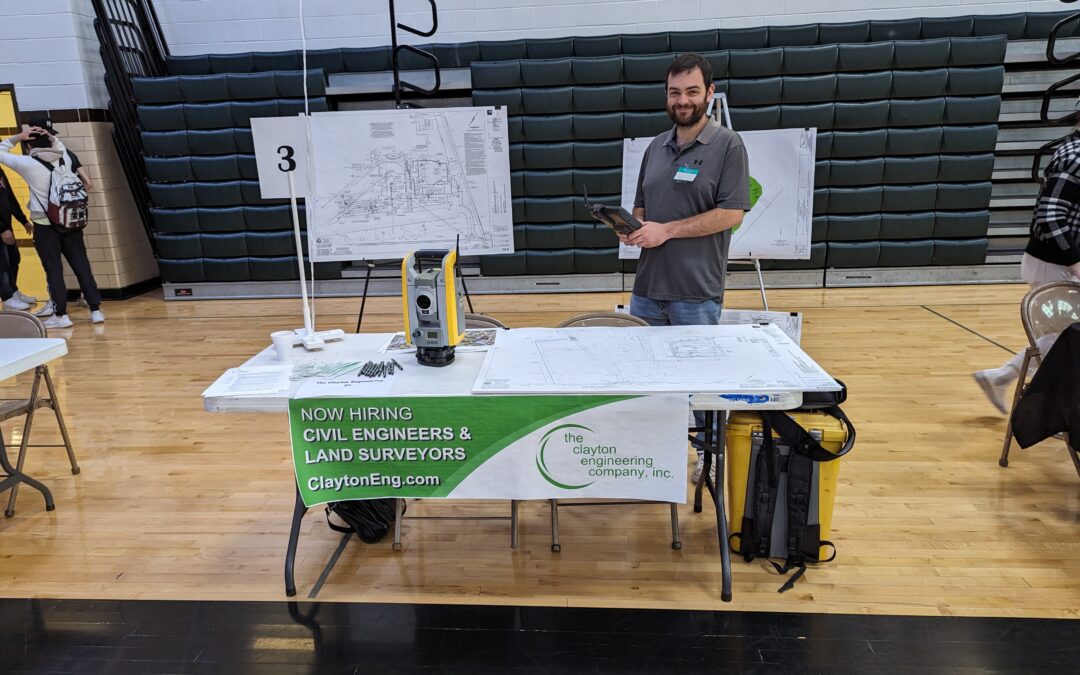

2024 Southern Illinois University Edwardsville Career Fair Clayton Engineering was a sponsor at the 2024 Engineering Career fair. We had lots of great conversations with students interested in professional opportunities after graduating and discussing...

by ClaytonEng1 | Sep 21, 2024 | News

Chicken N Pickle! 2024 CEC Co-Annual Outing We had a great time with each other September 20th at Chicken N Pickle in St. Charles. The food was great, a good volley or two happened on the pickleball court and the opportunity to socialiaze with one another after hours...

by ClaytonEng1 | Nov 10, 2023 | Education, News

It’s always a great day at the Mehlville Highschool Career fair, where we get to meet the next generation of potential civil engineers and surveyors. We met many eager, young minds who were considering careers in civil design and land survey. We like to wish the best...